These had to be carefully removed, so as not to disturb the copper sleeves in the cylinder head. Volvo Penta make a special, but rather expensive tool, for pulling the injectors out whilst bearing down on the copper sleeves to keep them in place. After lots of research, Peter decided to make his own, as the general consensus was that the Volvo tool was not up to the job and broke easily if the injectors were stubborn...in common layman's speak, 'made of toffee'.

Photo below shows home made sleeve cleaning tool (left), and home made injector puller (right).

Photo below shows home made injector puller in use.

When Peter refitted the refurbished injectors the engine started easily, however three of the cylinders suffered 'blow by' past the injectors. This meant the newly refurbished injectors were not seating correctly on the copper sleeves as they had before. Peter then made a home made sleeve cleaning tool from plywood (see 1st photo), and using 220 grit aluminium oxide abrasive paper, he meticulously and very carefully cleaned the seat of all 6 copper sleeves until they were all in perfect condition whilst changing the paper regularly, and manually blowing the dust out with a short length of hose.

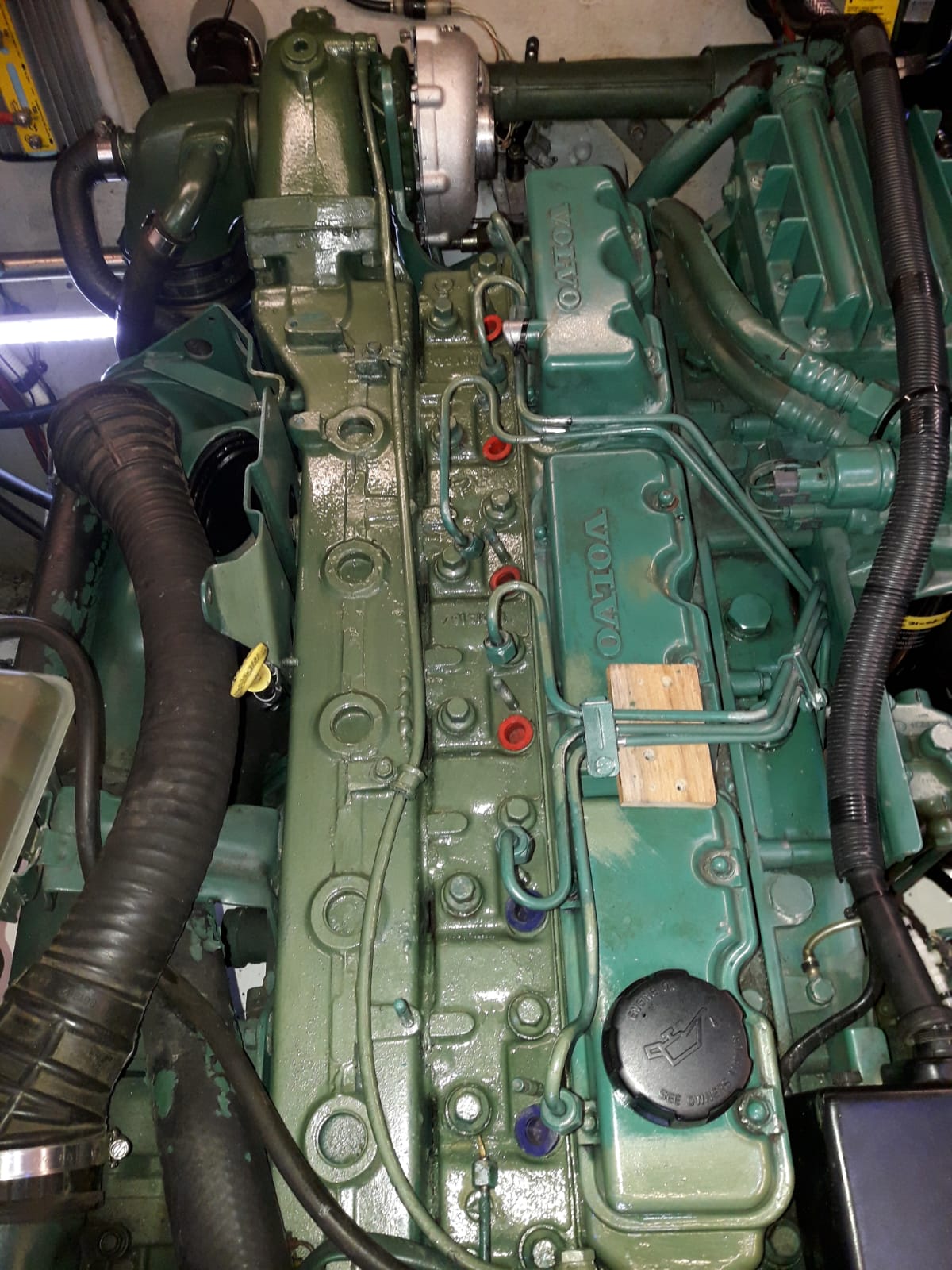

Once refitted, the 'blow by' had been cured, and the engine started and ran smoothly, whilst checking for fuel and coolant leaks. As everything was ok, all the unions were touched up with paint and all the air ducting and engine covers were refitted.

This weekend we took the opportunity to give Moonshine a test run out up the canal to a very cold and frosty Whitley.